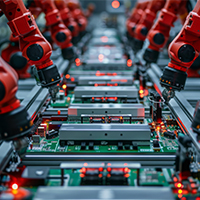

The Role of Automatic Screw Locking Machines in Modern Assembly Lines

In the realm of modern manufacturing, automatic screw locking machines have revolutionized the assembly process. These machines offer unparalleled benefits, especially in industries where precision and efficiency are paramount, such as electronics, automotive, and appliance manufacturing.

1. Enhanced Efficiency: Automatic screw locking machines streamline the assembly process by rapidly and accurately fastening screws, reducing the time required for manual labor. This increase in speed translates to higher production rates and lower operational costs.

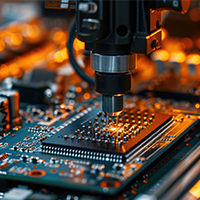

2. Precision and Consistency: These machines ensure consistent screw torque and depth, which is critical for maintaining the integrity and performance of assembled products. This precision reduces the likelihood of defects and enhances product reliability.

3. Labor Cost Reduction: By automating the screw fastening process, companies can significantly reduce the need for manual labor, thereby cutting labor costs and reallocating human resources to more complex tasks that require cognitive skills.

4. Safety Improvements: Automation minimizes the risk of repetitive strain injuries associated with manual screw fastening. The ergonomic design of automatic screw locking machines also contributes to a safer and more comfortable working environment.

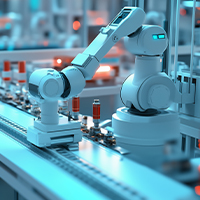

5. Adaptability and Flexibility: Modern automatic screw locking machines are designed to handle a variety of screw sizes and types, making them adaptable to different assembly requirements. Their programmable features allow for easy adjustments, catering to diverse production needs.

6. Quality Control: The integration of quality control systems in these machines ensures that each screw is fastened according to predefined specifications. Any deviations are immediately detected, allowing for real-time corrections and maintaining high-quality standards.

As manufacturing continues to evolve, the adoption of automatic screw locking machines will become increasingly essential. Their ability to enhance efficiency, precision, and safety makes them a critical component of modern assembly lines, driving innovation and competitiveness in the industry.