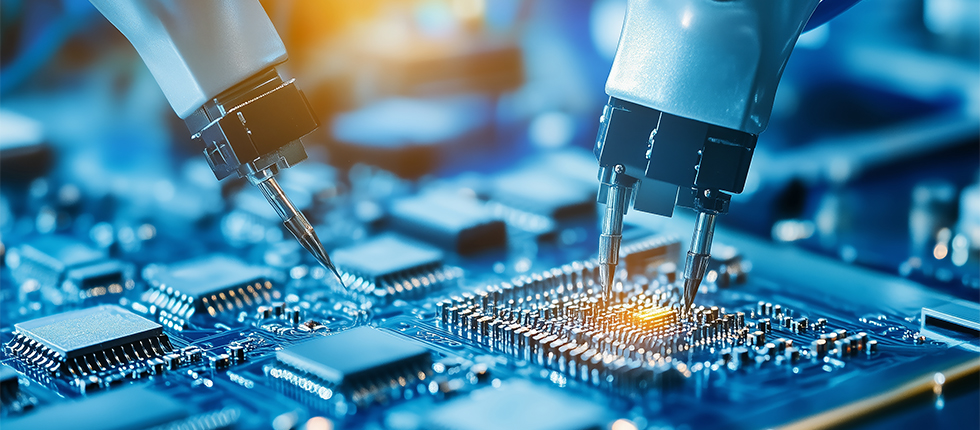

Key Factors to Consider When Choosing an Automatic Dispensing Machine

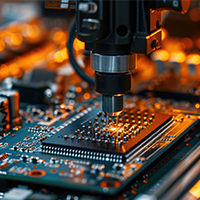

Key Factors to Consider When Choosing an Automatic Dispensing Machine An automatic dispensing machine is an indispensable piece of equipment in modern manufacturing, primarily used for high-precision dispensing operations by accurately controlling the flow and positioning of adhesives. When selecting an automatic dispensing machine, businesses need to consider the following key factors: 1.Type of Adhesive: Different products require different types of adhesives, such as silicone, epoxy, and UV adhesives. Therefore, it is essential to ensure that the dispensing machine can handle various adhesive viscosities and characteristics. 2.Dispensing Precision: The precision of dispensing directly impacts product quality and performance. A high-precision automatic dispensing machine ensures that adhesives are accurately applied to the designated spots, thereby improving product quality and consistency. 3.Ease of Operation: The user interface of the automatic dispensing machine should be simple and intuitive, making it easy to operate and maintain. A good user experience can lower operational difficulty and increase production efficiency. 4.Equipment Stability: The stability and reliability of the equipment directly affect the continuity and efficiency of the production line. High-quality automatic dispensing machines can operate stably over long periods, reducing downtime and malfunctions. By considering these factors, businesses can select the most suitable automatic dispensing machine to meet their production needs, thereby improving efficiency and product quality.